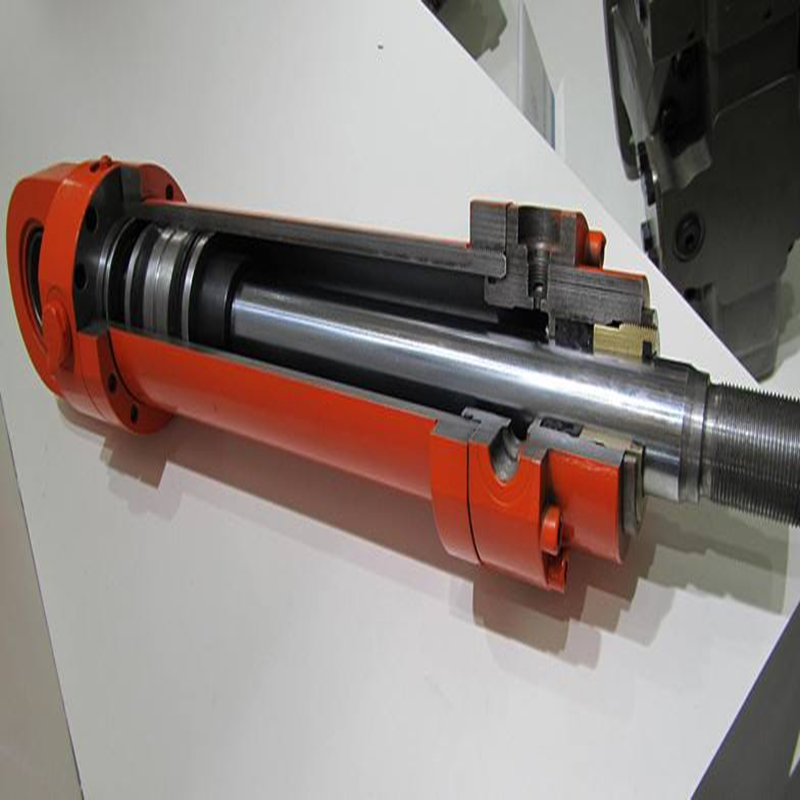

I-CK45 42CrMo4 I-Hard Chromed Plated Piston shaft rod Ye-Hydraulic Cylinder

Imininingwane Izithombe

Ukucaciswa Kwezobuchwepheshe

| Ububanzi | 6-300 mm |

| Ubude | 100mm-1200mm |

| Ibanga lensimbi | I-DIN CK45I-JIS 45C Idatha ye-ASTM1045 Idatha ye-SAE1045 I-AISI 1045 |

| Ukubekezelelana | ISO f7 |

| Ubukhulu be-Chrome | 20μm(amaminithi) |

| Ukuqina kwesendlalelo se-chrome | 850HV(amaminithi) |

| Ubulukhuni | I-Ra 0.2μm(ubukhulu) |

| Ukuqondile | 0.2/1000mm |

| Izakhiwo zikaMechanical(ck45) | Amandla okukhiqiza≥20MpaAmandla e-Tensile≥80 MpaUbude≥5% |

| Isimo sokuhlinzeka | 1.I-chrome eqinile |

| 2.Ukungeniswa kwaqina | |

| 3.Icinyiwe futhi Iqinile | |

| 4.Ukungeniswa kuqiniswe nge-Q&T |

Ukwakheka Kwamakhemikhali

| Okubalulekile | C% | Mn% | Si% | S% | P% | V% | Cr% |

| Ck45 | 0.42-0,50 | 0.50-0.80 | 0.17-0.37 | ≤0.035 | ≤0.035 |

| ≤0.25 |

| ST52 | ≤0.22 | ≤1.6 | ≤0.55 | ≤0.04 | ≤0.04 | 0.02-0.15 |

|

| 20MnV6 | 0.17-0.24 | 1.30-1.70 | 0.10-0.50 | ≤0.035 | ≤0.035 | 0.10-0.20 | ≤0.30 |

| 42CrMo4 | 0.38-0.45 | 0.50-0.80 | 0.17-0.37 | ≤0.035 | ≤0.035 | 0.07-0.12 | 0.90-1.20 |

| 40Kr | 0.37-0.45 | 0.50-0.80 | 0.17-0.37 | ≤0.035 | ≤0.035 |

| 0.80-1.10 |

Izakhiwo Zemishini

| Okubalulekile | I-TS N/MM2 | YS N/MM2 | E%(MIN) | UCHARPY | ISIMO |

| CK45 | 610 | 355 | 15 | > 41J | JIKELELE |

| CK45 | 800 | 630 | 20 | > 41J | Q + T |

| ST52 | 500 | 355 | 22 |

| JIKELELE |

| 20MnV6 | 750 | 590 | 12 | > 40J | JIKELELE |

| 42CrMo4 | 980 | 850 | 14 | > 47J | Q + T |

| 40Kr | 1000 | 800 | 10 |

| Q + T |

Ukupakisha

Amafutha e-anti-rust kunduku ngayinye

Amafutha e-anti-rust kunduku ngayinye

Umkhono wephepha kwintonga ngayinye

Noma Ngokuvumelana Nezidingo Zekhasimende.

Sihlose Ukwaneliseka Kwakho!

Isicelo

Ikakhulu isetshenziselwa amasilinda amanzi, amasilinda womoya, izinsika zomhlahlandlela

kulezi zisetshenziswa ezilandelayo:

Imishini Yokwakha, Ama-Manipulators, Imishini Yezimayini, I-Texitile Machniery, Imishini Yokuphrinta.